Public health concerns about food safety from a microbiological perspective have increased worldwide in recent years.

In the United States alone, it is estimated that nearly 9.4 million sick people, 55,961 hospitalisations and 1,351 deaths are caused each year by the consumption of food contaminated with 31 food pathogens.

Infections or outbreaks caused by these pathogens can be the result of consuming contaminated food, including beef, dairy products, fresh vegetables and contaminated water.

Therefore, it is important to monitor and control the main known pathogens in food processing and environmental conditions.

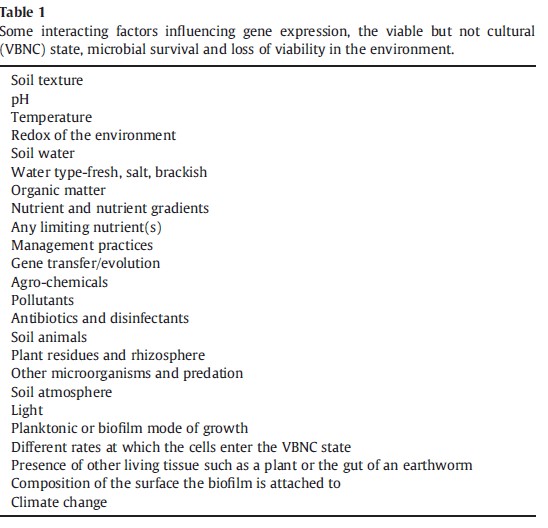

Microorganisms are subjected to various stress conditions not only in nature, but also during food processing, which presents a great challenge for them to survive under adverse conditions.

Consequently, micro-organisms have developed unique adaptive strategies to resist and maintain survival under hostile conditions.

In fact, during food processing, exposure to adverse conditions such as heating, freezing, drying, freeze-drying, irradiation (e.g. UV), high water pressure, etc. is a major challenge for microorganisms. UV), high hydrostatic pressure, fermentation or the addition of antimicrobials and chemicals, can induce different physiological states in bacteria, and increase the possibility of inducing the transition to survival mechanisms including spore formation or the transition for non-spore-forming microorganisms to viable but not culturable cells (VBNC).

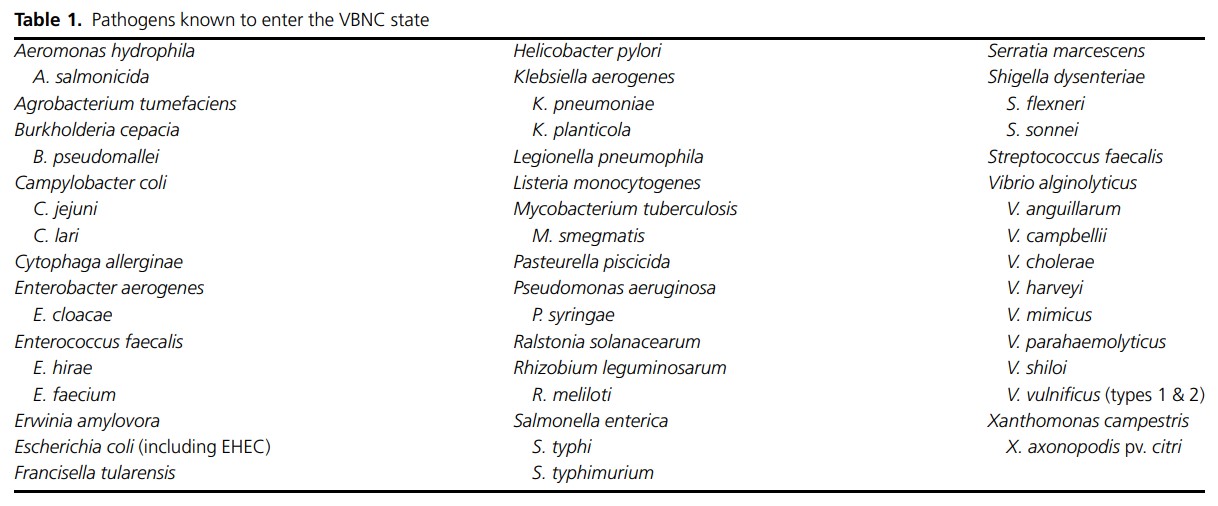

To date, more than 60 bacterial species capable of entering the VBNC state have been identified, including Escherichia, Vibrio, Listeria and Pseudomonas.

VBNC cell properties

VBNC cells have some specific characteristics.

Compared to dead cells, VBNC cells have an intact membrane, successfully maintain gene expression and avoid cytoplasmic leakage.

In contrast, dead cells have a damaged membrane and are metabolically inactive.

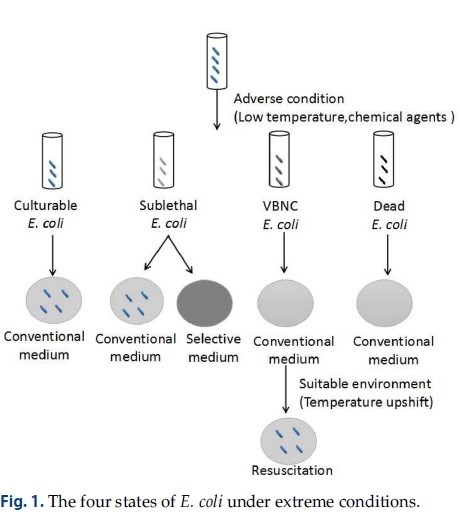

Similarly, compared to viable and sub-lethally damaged cells, VBNC cells cannot grow in the standard medium, which is a specific character of VBNC cells. Furthermore, physiological and molecular differences exist between VBNC cells and viable and culturable cells, including cell wall and membrane compositions, gene expression, adhesion properties, virulence potential, metabolism, cell morphology, and physical and chemical resistance.

For instance, cell size reduction was found in VBNC E. coli, while cell dwarfing and round cells were described for some VBNC cells. Furthermore, VBNC cells have a low metabolism and a high ATP level. However, the mechanism by which bacteria adapt to the VBNC state remains unclear.

The ability to return to the viable state is also an advantageous feature of VBNC cells, and in the scientific literature this process is described as ‘resuscitation’. Resuscitation is a very important feature of VBNC bacteria. VBNC cells that respond to appropriate environmental stimuli, such as an increase in temperature or the addition of nutrients, become metabolically active and culturable again.

This implies that appropriate conditions could be provided during food processing for the resurrection of VBNC bacteria, leading to a risk in terms of food quality and safety. Indeed, many pathogenic bacteria in the VBNC state are not able to initiate infection, but retain virulence potential, which will only be expressed following resuscitation.

This is why their control poses a great challenge to the food industry.

Identification of VBNC cells

In the VBNC state, bacteria cannot grow on conventional media and can therefore evade conventional detection methods.

In fact, micro-organisms in the non-culturable state, not growing on the routine bacteriological media on which they would normally grow and develop into colonies, can cause numerous false negatives. An example is given below for E. coli, where the presence of VBNC from E. coli makes its monitoring more difficult and is likely to produce false negative results.

As a result, while for a long time it was believed that a bacterial cell died when it was no longer able to grow on normal culture media, we now know that this assumption is simplistic and that there are many situations in which a cell loses viability but remains viable and potentially able to regrow.

Because of this, the detection of VBNC cells presents a major challenge as they can be the source of a potential food safety and human health risk.

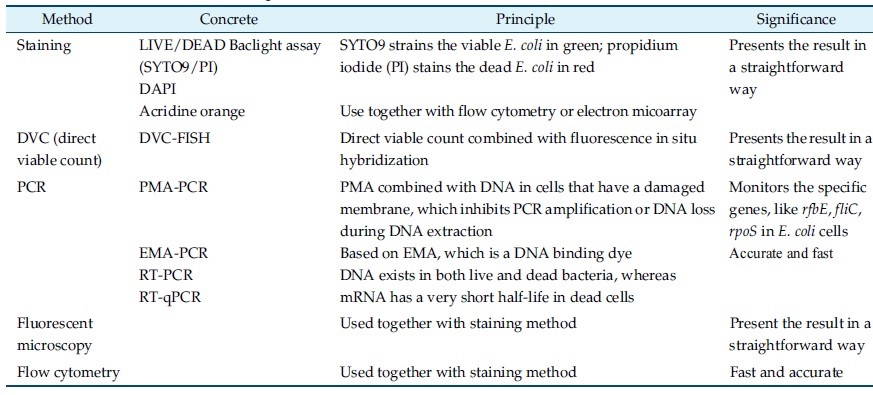

Since cells in the VBNC state are no longer culturable, alternative ‘non-culture’ methods must be used in order to prove that cells in this state are alive. The table below lists some of the methods reported in the literature that can be used to detect VBNC cells. These are complemented by even more modern approaches such as metagenomics, which combines PCR with bioinformatic analysis, and MALDI-TOF technology.

Advances in molecular technologies have made it possible to understand how traditional microbiology methods are able to estimate less than 1% of the approximately 109 bacterial cells in one gram of medium.

These studies concluded that the standard incubation times used in laboratory experiments were insufficient for the bacterial growth of a number of microbial strains and a large part of this underestimation is due to the presence of non-culturable cells.

The lack of information that exists of the remaining 99% of the microbial population is not insignificant as it can be crucial in understanding various phenomena such as biofilm formation, the emergence of resistance, and quorum sensing (QM), the mechanisms of which have yet to be exactly deciphered in many species.

The Piramide and Realco approach

For the above reasons, it is essential for the food industry (and beyond) to implement specific actions to control biofilm contamination.

To this end, the application of the Biorem® patent is useful. Through the action of several enzyme classes selected for their specific activity on biofilms, it allows biofilms to be effectively eliminated both in closed systems and on open surfaces, reducing the risk linked to the presence of microorganisms in the state of non-culturable cells, and their possible resurrection.

The support of Piramide and its team of experts does not stop with the Biorem® treatment, but complements this with the study and characterisation of the contaminants contained in the Biorem® washing solution.

The investigation is carried out not only using traditional microbiology methods, but also more modern approaches such as metagenomics and cytofluorimetry.

This makes it possible to get a closer snapshot of the microbial population present in a given environment, and thus go beyond the 1% identification limit.

Piramide ‘s technical and scientific expertise supports the customer in the correct interpretation of data and the definition of specific prevention and screening protocols.

Bibliographic references

- Significance of Viable but Nonculturable Escherichia coli: Induction, Detection, and Control (Tian Ding et al., 2016)

- Effects of quorum sensing on the biofilm formation and viable but non-culturable state ( Jiahui Li et. Al, 2020)

- Roles of Aerotolerance, Biofilm Formation, and Viable but Non-Culturable State in the Survival of Campylobacter jejuni in Poultry Processing Environments (Diksha Pokhrel et al., 2022)

- Viable but non-culturable (VBNC) bacteria: Gene expression in planktonic and biofilm cells (J.T. Trevors, 2011)

- Biofilms in drinking water and their role as reservoir for pathogens (Jost Wingender et al., 2011)

- UV Disinfection Induces a Vbnc State in Escherichia coli and Pseudomonas aeruginosa (Shenghua Zhang et al., 2016)

For more information, ask our experts:

Tel: 0332 826017

Email: av@piramide-ambiente.it