Solutions for different needs

Oxygen measurement: different solutions for every need

In the beer and beverage industry, the content of dissolved carbon dioxide (CO2) and oxygen (O2) are decisive factors for the quality, taste and flavour stability of beer and carbonated beverages.

In particular, O2 is an important parameter as it causes a rapid decline in flavour stability and shelf life.

Breweries and beverage producers continuously monitor and measure CO2 and O2 concentrations during production.

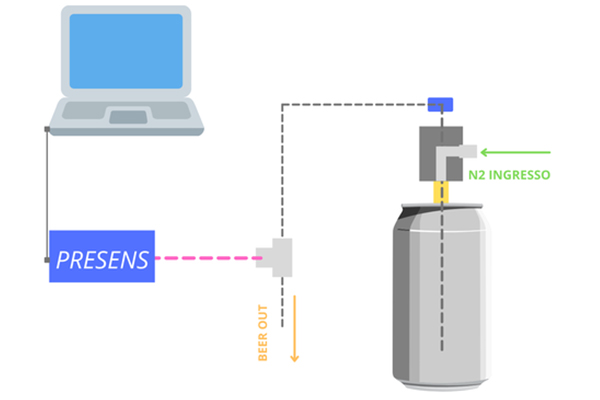

PRESENT portable oximeter

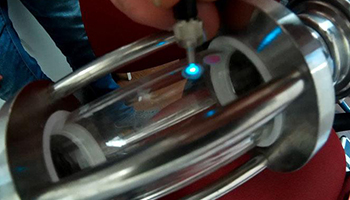

The Presens system is very simple yet extremely precise, and consists of only three elements:

- The signal emitter/receiver

- An optical fibre (which carries the signal)

- The sensor (signal receiving part, applied inside the container)

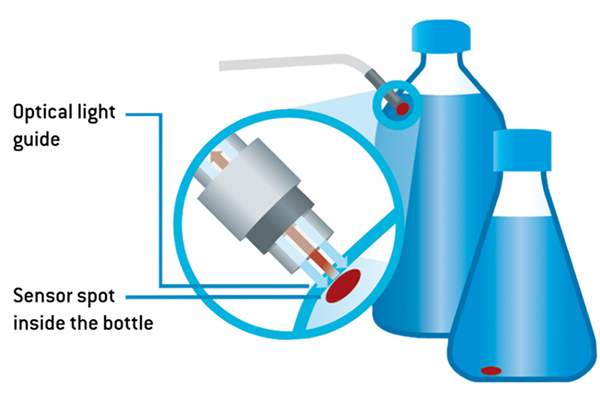

The precise emitter, connected to the computer, emits a light signal specific to that sensor (depending on its calibration); the signal travels through the optical fibre until it hits the receiving part ( pink ) of the sensor located inside the container.

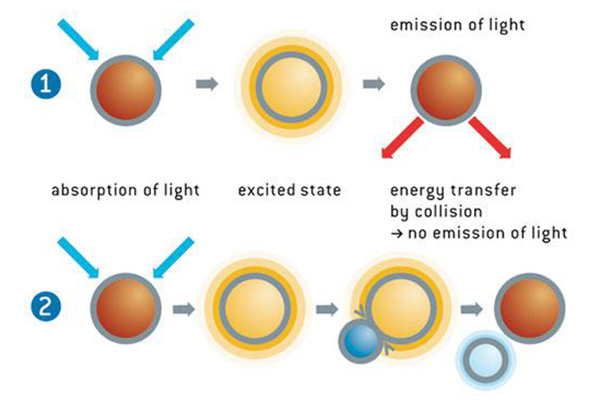

The sensor absorbs the light and goes into an excited state.

Depending on the amount of oxygen present in the medium (whether in liquid or gas phase), the sensor will emit a return light beam which is intercepted by the optical fibre and returned to the signal emitter, which by handling this return signal is able to measure the amount of oxygen present with extreme precision [1 ppb].

What are the advantages over a traditional system?

- No need for calibration, the sensors are already calibrated at the factory

- Low cost of the sensors, which can be excited up to 10000 times, after which they must be replaced

- In-line measurement is non-invasive, without loss of product

- Sensors can be easily washed and sanitised in-line (no soda ash or peracetic) with a single instrument I can analyse several sensors without interrupting the process cycle

- Measurement is truly continuous with a settable minimum of one measurement every 3 seconds

- You can conveniently analyse the data and make graphs in Excel of the continuous measurement

- The system requires no maintenance other than replacing the sensors when they reach the end of their life.

Measuring in bottles and cans

Thanks to the use of a piercer and a specific and sensitive sensor at low oxygen concentrations (ppb), it is possible to measure the oxygen content in the bottle and/or can immediately after packaging, thus obtaining precise and accurate data.

Measurement in LINE

The same sensors can be applied in-line, mounted on specially designed mirrors to measure the oxygen concentration in ppb on finished beer during transfers.

These measurements can be made directly in-line, without loss of product, thus reducing the risk of contamination due to opening taps.

Sensitive sensors for higher oxygen concentrations (ppm) can also be used for measurements on wort.

Accessories for measuring oxygen in cans

HAFFMANS PENTAIR Oxy-2-GO full line

For small breweries in need of an inexpensive yet reliable dissolved oxygen (DO) content measuring device, the Pentair Haffmans Oxy-2Go is the answer.

Oxy-2Go is a portable device for measuring the oxygen content of wort, beer or other carbonated beverages, developed with proven Pentair Haffmans optical technology. Oxy-2Go provides small breweries with access to an oxymeter without a significant hardware investment.

Haffmans Pentair’s integrated optical technology offers reproducible and reliable readings.

ADVANTAGES

- Economical yet high-performance system

- Small size and easily transportable

- Does not require a connected PC

- Quality and reliability guaranteed by decades of Haffmans’ experience in the industry

GMT analogue or i-DGM digital aphrometer

The analogue CO2 Gehaltemeter, type GMT, enables fast and accurate determination of the CO2 content in beer and carbonated beverages according to Henry’s Law.

The measurement results are reproducible and do not depend on the operator.

Once the sample has been taken, equilibrium is automatically created within the chamber: the operator must note the pressure from the pressure gauge and the temperature from the thermometer, and use the two data to calculate the CO2 content.

The GMT can only be used for tank measurements.

The intelligent CO2 meter, type i-DGM, enables fast and accurate determination of the CO2 content in beer and carbonated beverages according to Henry’s law.

The i-DGM enables high product pressure, making it also suitable for the soft drinks industry.

Up to 10 different product types can be programmed into the i-DGM. The protective shell protects the i-DGM from physical impact in harsh environments.

After identification of the operator/location, sampling takes place.

The dissolved CO2 content is calculated and displayed electronically. Data can be securely transferred to a PC using the interface cable.

Can be used in-line but also for bottle/can measurements with the appropriate piercing tool.

c-DGM, the complete solution for measuring oxygen and CO2 at all points of the process

The CO2/O2 Gehaltemeter, type c-DGM, combines the internationally accepted determination of dissolved CO2 content based on Henry’s law with a highly accurate measurement of dissolved O2.

This state-of-the-art optical O2 measurement technology is significantly improved over traditional O2 measuring instruments and does not require frequent calibration. Its design allows for greater product pressure, making it suitable for the soft drinks industry.

Up to 10 different product types can be programmed into the device. The protective shell protects the c-DGM from physical impact in harsh environments.

When the CO2 measurement is started, the O2 content is stored.

Automatically, equilibrium is created, followed by the measurement of pressure and temperature. The dissolved CO2 content is then calculated and displayed electronically. The data can be securely transferred to a PC using the interface cable.

In addition to combined CO2/O2 measurement, the c-DGM is suitable for single O2, continuous O2 and single CO2 measurements.

The Total Package Oxygen (TPO) value, based on the Uhlig method, is also calculated in the CO2 / TPO measurement mode and in the single TPO measurement.