Pascalised juices and purees

An old theory recently applied

In 1899, the American scientist Hite theorised about the use of high hydrostatic pressure to prolong the shelf life of milk.

Unfortunately, he did not have the technology to put this technique into practice. Very high pressures in the range of 1000-10000 bar are used for sterilisation treatment.

In recent years, however, equipment has been developed that can support the application of such high hydrostatic pressures.

This new equipment therefore makes it possible to offer the consumer a product that is safe from a hygienic-sanitary point of view without great losses in terms of organoleptic and nutritional characteristics.

How does it work?

The sterilising effect is achieved by mechanically damaging the micro-organism’s cell membrane and deforming its outer wall, as well as inactivating the germ’s enzymes.

Denaturation of membrane proteins causes the blocking of exchanges with the outside world, and damage to enzymes crucial to metabolism prevents multiplication, leading to the death of the bacterium.

This process tends to take place at room temperature, with an average increase in food temperature of around 20°C due to the pressure exerted (from 20°C to 40-45°C).

The increase in temperature is, however, negligible and allows, among other things, the most thermolabile components such as vitamins to remain unaltered.

The availability of pascalised fruit purees and juices is ideal for the safe production of beers with added fruit (e.g. berliner weisse, goose, fruit IPA, NEIPA), without the risk of undesirable microbial contamination that could adversely affect product characteristics.

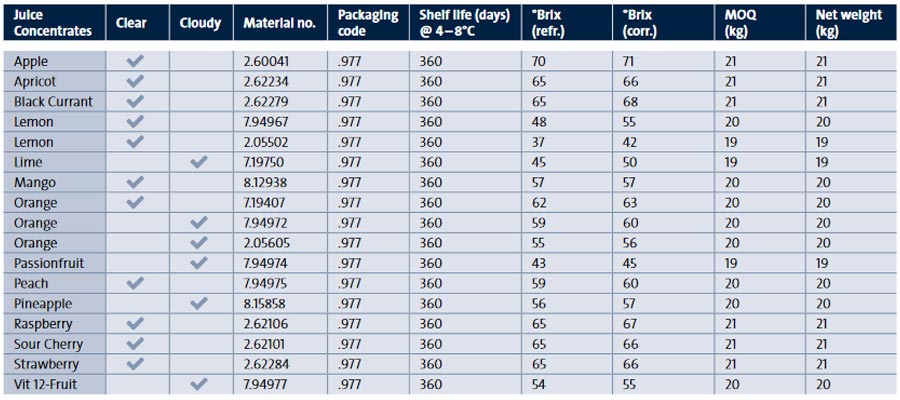

Portfolio

Frozen Concentrated Juices

Concentrated juices are also available in frozen form. In this case, they are non-sterile products, so the advice is to add them at the end of boiling.

Unlike frozen purees, juices are highly concentrated in terms of both sugars and organic components, so heat treatment is more tolerated.