A unique range for your brewery

Pyramid Problem Solving Programme specific programme for solving problems of unwanted contamination in the brewery

Cleaning for Craft Breweries

Our Products

Born from research, our enzymatic formulations dedicated to craft breweries specifically respond to the need for deep cleaning of installations, facilitating the subsequent disinfection action to remove any bacteria.

Furthermore, with the BIOREM range, we respond to the need to eliminate contamination for a perfect finished product.

With a view to an integral service, and to complement our enzymatic washing protocols, we provide customers using our enzymatic formulations with brewery-specific products selected by us.

From alkaline to acid descaling agents, from chloractives to peracetics for sanitisation.

Enzyme specialities

Think of a detergent that does not exist, create it with respect for nature.

Our enzymatic specialities:

- ENZYBRAS 4.1

- ENZYBREW L

ENZYBRAS 4.1

- Enzymatic Activity

- Effective

Powdered enzyme cleaner based on ENZYMES and ACTIVE OXYGEN, phosphorus-free, surfactant-free, EDTA-free.

- 100% biodegradable

- 100% deep cleansing

ENZYBREW L

Liquid enzymatic cleaner for filling machines, pipes and for soaking removable parts. Phosphorus-free, EDTA-free.

Biorem Line

Specifically formulated to improve plant hygiene, covered by a worldwide patent.

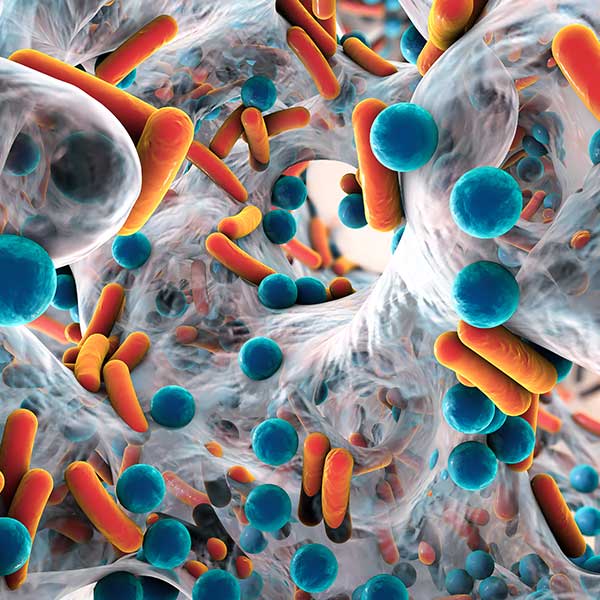

Biofilm is a constant source of contamination, created by an accumulation of bacteria and yeasts that develop a protective matrix consisting of organic polymers (EPS): polysaccharides, proteins, DNA, lipids, etc…

This organic matrix is very difficult or even impossible to remove using conventional cleaning methods and usual disinfection protocols.

In craft breweries, the application of the BIOREM® patent, especially for exchangers and packaging lines, makes it possible to eliminate contamination by micro-organisms frequently linked to biofilms:

- Brettanomyces

- Lactic bacteria

- S. Diastaticus contaminants

- Acetic bacteria

- Candida

Specific chemical range for craft breweries

ALKALINE CHEMICALS

- ALKABREW non-foaming full alkalinity booster

- OXYBREW alkaline phase booster

DESCALING ACIDS

- nitric-phosphoric ACIDBREW

- PI-ACID SF organic nitrogen and phosphorus free

CHLORINE ALKALINE

- DRAFTBREW sanitiser plug-in systems

SANITIZERS

- P550 peracetic acid 5%

- P5 1 O peracetic acid 15 %

- P900CIDE acidified hydrogen peroxide

- ISOFASTER isopropyl alcohol-based non-residual sanitiser

FOAMMERS

- FOAMBREW Cl chlorine-foaming agent

- FOAMBREW AC nitric-phosphoric foaming agent

- FOAMBREW CT acidified hydrogen peroxide foaming agent

- OKORON 13 peracetic acid foaming agent

- FOAMBREW AL alkaline foaming agent

Services

Piramide offers innovative brewery services:

- Microbiological RESET of plants with BIOREM treatments carried out by specialised personnel

- Consulting for customised hygiene plans

- PSP – Problem Solving Program exclusive Pyramid service for the brewery sector.

Filling machines

Plant and cellar

Drum washer

PSP - Problem Solving Programme

RAISING AWARENESS IN BREWING

Piramide‘s experience in solving problems of unwanted contamination in breweries has led to the realisation that it is also increasingly necessary to investigate the causes.

Only a full AWARENESS of the origin and causes of a problem can help to avoid relapsing into the same problem after some time. The Piramide Problem Solving Programme was created for this purpose.

The Problem Solving Program is an exclusive Pyramid service aimed at the brewery sector.

The combination of specific microbiological, chemical and cleaning skills, supported by an analytical service with rapid and modern analysis technologies, enables a 360° investigation of any problems encountered in the brewery, with the aim of

- Circumscribe the causes of the problem

- Establish corrective actions

- Validate the effectiveness of the actions taken

- Establish ‘customised’ guidelines to reduce risk in the future

Thanks to the PSP programme Pyramid extends its service from problem resolution to problem definition, thereby increasing the brewer’s AWARENESS.

Our equipment

A passion for excellence guided our choice of transfer piping designed for craft breweries, dosing systems and open surface skimming stations.

The control of hygiene practices is fundamental, which is why we selected state-of-the-art measuring instruments and evaluation methods: contaminant detection audits, metagenetic analysis, measuring instruments (pH, conductivity, luminescence).

Dosage

Skimming

Pipes

Dosage

Skimming

Pipes

Rental of instrumentation for detergency and hygiene control: pH meter, Bioluminometer, Conductivity meter

With the method and products of the BIOREM range you detect, identify and remove all biofilm contamination. You increase productivity, ensure quality, extend the life of your products.