Unique, patented multienzyme solution to treat biofilm problems curatively and preventively.

Controlling contamination in life sciences

Bacteria such as Ralstonia picketi, Burkholderia Cepacia, Escherichia coli, etc. can develop biofilms in various production equipment and water circuits.

This can lead to serious contamination, non-conformities, and production interruptions. It is therefore essential to protect your equipment effectively and sustainably!

Drifts can occur within production equipment or water networks, certain bacteria such as Ralstonia picketi can proliferate and affect the quality of water (EP, EPPI) and the finished product.

The European Pharmacopoeia imposes the following specifications for CBT:

- EP : ≤ 100 CFU / ml

- EPPI : ≤ 10 CFU / 100 ml

A loss of control could have serious consequences that could affect the quality of the drug and its safety, which could harm public health.

A production stoppage would also be dramatic for any manufacturer.

It is therefore essential to control contamination risks, which means knowing how to detect them.

Protect your water circuits (EP, EPPI) and production equipment with our rigorous approach that includes techniques and tools adapted to the problem of biofilms.

Only total control can guarantee compliant and sustainable hygiene.

What is a biofilm?

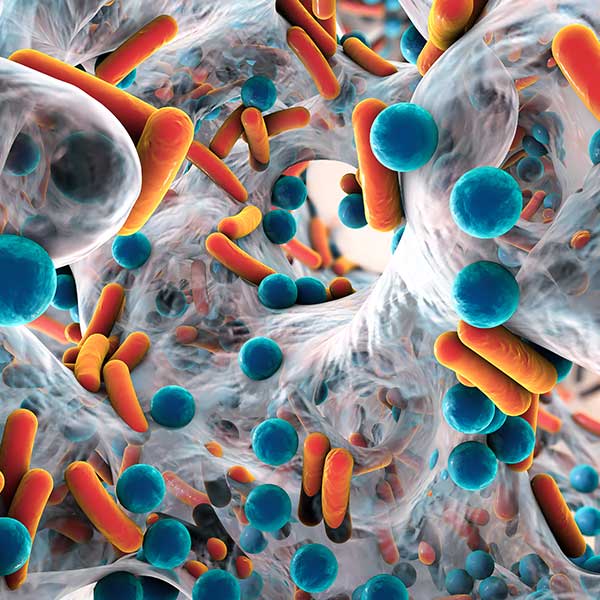

A biofilm is an accumulation of bacteria that develop a protective matrix, making them extremely resistant to cleaning and disinfection.

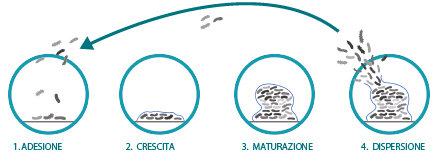

The biofilm development cycle

A biofilm begins with the adhesion of bacteria to a surface (1).

They develop a matrix to protect themselves and provide favourable conditions for their multiplication (2).

Well-established in this protected environment, they proliferate (3).

In the maturation phase, the biofilm fragments and/or releases bacteria (4) in an unpredictable manner (planktonic shower) and contaminates other downstream equipment.

A biofilm is thus a permanent source of contamination.

Biofilm resistance

Biofilms can resist external aggression (thermal, mechanical, chemical, …).

Numerous scientific studies have shown that enzymes are the best solution to degrade them (Bridier et al., 2015; Delhalle et al., 2020; Lefebvre et al., 2016; Lequette et al., 2010; Nagaraj et al., 2017; Oulahal et al., 2007; Stiefel et al., 2016; Tsiaprazi-Stamou et al.2019).

Why is the enzymatic solution more effective than traditional chemistry?

Our enzymatic products are the only ones capable of irreversibly degrading all the constituents of the protective matrix of biofilms (DNA, polysaccharides, proteins, lipids, etc.).

This patented treatment will ensure effective disinfection

guaranteeing access to the biocide for all microorganisms present in the systems.

A comprehensive and unique approach that includes:

1 – The investigation of the problem

2 – The characterisation of bacteria

3 – The extraction of biofilms from implants and/or networks

4 – The protection of your implants to prevent the reappearance of biofilms

Our analysis methods include:

- The quantification of bacteria

- The identification of biofilmogenic bacteria

- An accurate total bacteria count

- The characterisation of the flora

Piramide and BAMA join forces and expertise to propose a unique solution for the Life Sciences sector!

Purified water (EP) or water for injection (EPPI) distribution systems are not always designed for chemical treatment or disinfection and may be subject to aggression related in particular to water quality (rouging), the use of steam for sanitisation (rouging, blacking) or the use of ozone (yellowing).

It has been scientifically proven that these aggressions cause an alteration of the condition of the surfaces of these nets, phenomena that promote the anchoring of bacteria and the development of biofilms (Telegdi et al., 2017).

Expert in the chemical treatment of stainless steel (rouging, blacking, passivation, …) in the Life Sciences sector, BAMA is the ideal partner to implement these treatments: creation of a momentary loop, heating of fluids, use of washing heads.

A biofilm removal treatment can thus be combined with a derouging treatment to fully protect your facilities.

- Patented

- PDE

- Residue-free validation method