The context

During 2010, a number of cases of colour alterations in mozzarella (so-called ‘blue mozzarellas’) were brought to the attention of the public with great media coverage.

The phenomenon that caused a scandal was when a consumer opening a packet of mozzarella, purchased at a supermarket, noticed that the product inside had a diffuse blue-blue colouring.

It was soon discovered that the discolouration was caused by a non-pathogenic saprophytic bacterium that loves humid environments and proliferates happily in very humid food products, Pseudomonas.

In order to provide an up-to-date picture of knowledge on Pseudomonas spp., recognised as one of the bacteria most involved in food spoilage, the following fact sheet was drawn up.

Pseudomonas SPP.: an altering bacterium

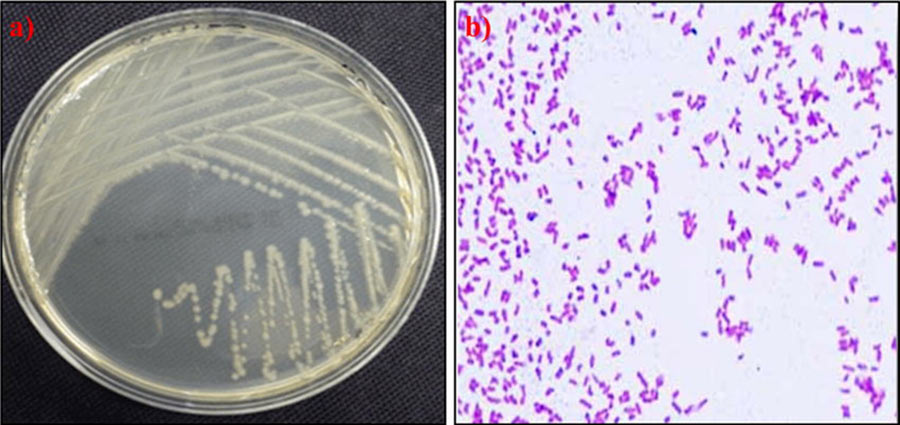

Pseudomonas spp. is a Gram-negative psychotroph frequently isolated from milk and dairy products.

In particular, Pseudomonas fluorescens is one of the most common species isolated from milk and dairy products (Pisano et al., 2016; Scatamburlo et al., 2015; Martin et al., 2011; Ogier et al., 2002), and its ability to spoil milk and cheese is due to its ability to produce a wide range of extracellular enzymes (De Jonghe et al., 2011), and the production of a blue (indigo-like) pigment.

Pseudomonas cells are easily inactivated by high temperatures, but their enzymes are heat-stable and can cause food spoilage even after cell death (Chen et al., 2003; Marchand et al., 2009).

Pseudomonas spp. and food spoilage

Pseudomonas spp. and other psychrotrophic bacteria are the contaminants in the microbial spoilage of mozzarella (Baruzzi et al., 2012). Mozzarella is a typical Italian cheese whose manufacturing process is characterised by the spinning of the curd.

Contamination of mozzarella can occur at two production stages, generating several problems:

- Before the heat treatment: thermostable enzymes can induce instability in the final product, leading to changes in the hardness, dissolvability and extensibility of the mozzarella (Oommen et al., 2002).

- After the heating process (Baruzzi et al., 2012), the most common contamination occurs.

The interest in the role of Pseudomonas spp., the species Pseudomonas fluorescens in particular, in the spoilage of mozzarella cheese increased just after the summer of 2010 when the ‘blue mozzarella’ spread in Italy and then spread to many European countries (Nogarol et al., 2013; Andreani et al., 2014).

From a technical point of view, it can be said that this colour alteration can occur in moist and not particularly acidic cheeses, when the hygienic conditions of the production environment or of the water used in processing are not adequate. It is no coincidence that products particularly prone to contamination include soft cheeses such as Mozzarella, characterised by a high moisture content (50-80%) and neutral pH (5.0-6.5).

The absolute absence of Pseudomonas spp in the dairy can never be achieved; however, with appropriate measures, it is possible to keep the level of contamination very low and make the occurrence of defects much less likely.

Another technical note concerns the storage conditions applied, i.e. temperature and time. Correct application of cold often avoids (or eases) the problem, as is also the case with storage that is not excessively prolonged in time, which, however, goes against the market requirements of a product with an ever increasing shelf life.

Diffusion P. fluorescens

P. fluorescens is recognised for its high ability to adhere and form biofilms on milk tanks and at various points of production (tubes, multipurpose pasteurisers, coagulators, firming tanks) (Carrascosa et al., 2015; The et al., 2012); the latter property provides it with protection against adverse conditions such as cleaning processes (CIP) (Cherif-Antar et al., 2016). Biofilm, in fact, helps microorganisms to persist in the environment and improve their ability to resist drying, UV radiation and treatments with disinfectants and antimicrobials (Di Bonaventura et al., 2008).

The most recent scientific studies have shown a relationship between pigment production and the ability of Pseudomonas fluorescens to form biofilms, indicating that these characteristics could together be related to the ‘blue mozzarella event’.

Bacterial cells associated with a biofilm areoften in the available but non-culturable cell (VBNC) state, in which cells take on different physiological characteristics.

Although several studies are available that report on the level of contamination of dairy products by the cultivable population of Pseudomonas spp. (Carraro et al., 2011; Conte et al., 2011; Martin et al., 2011), there is little information on the activity of Pseudomonas spp. in the available but non-culturable cell state (VBNC).

The emergence of VBNC microbial cells can be caused by multiple stresses (chemical or heat shock, osmotic stress and dehydration) that occur during production and storage processes. In the VBNC state, the cells retain most of their metabolic activities, thus affecting the quality and shelf life of the product when they return to their planktonic state. Their transition to VBNC, on the other hand, makes them difficult to detect using classical microbiology methods.

The BIOREM® curative treatment adopted by Piramide for the removal of Pseudomonas

It is no coincidence, therefore, that theintervention of Piramide, a leading company in enzyme technology, is increasingly being requested by manufacturers in order to understand and resolve Pseudomonas contamination associated with the presence of biofilms resistant to sanitisation protocols.

The enzymatic approach of the international BIOREM® patent proposed by Piramide Ambiente and Realco represents an effective and resolving solution that enables production safety.

For more information, ask our experts:

Tel: 0332 826017

Email: av@piramide-ambiente.it